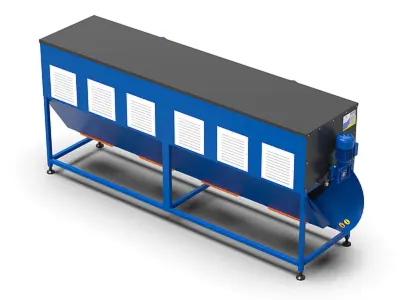

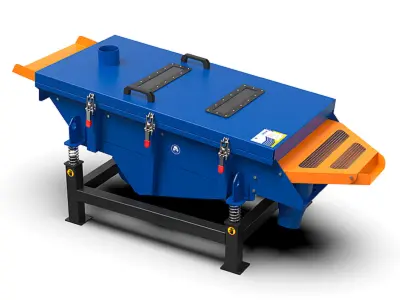

Calibrators, vibrating tables, pellet coolers

Calibrators, vibrating tables, and pellet coolers from TechnoMashStroy (Ukraine) are specialized equipment for processing and finishing granular materials at agro-industrial, feed, food, chemical, and other enterprises. The equipment is designed for sorting, fractionating, cooling, and stabilizing finished pellets after granulation.

Advantages of TechnoMashStroy equipment:

- Efficient calibration — calibrators precisely separate pellets by size, remove dust, fine fractions, and malformed pellets, improving product quality.

- Uniform cooling — pellet coolers rapidly lower product temperature to the required level, preventing deformation and brittleness, and extending storage life.

- Optimization of physical and mechanical properties — vibrating tables distribute pellets evenly, remove excess moisture and impurities, and stabilize material structure.

- Application flexibility — suitable for various types of pellets: feed, fuel pellets, fertilizers, feed additives, and more.

- Automation and integration — can be integrated into production lines, with adjustable operation parameters based on material characteristics.

- Resource saving — modern solutions reduce raw material losses, minimize energy consumption, and increase the yield of finished products.

- Easy maintenance — convenient design provides fast access to key components for cleaning and maintenance.

- Operational safety — equipment is equipped with protection systems and emergency blocking.

Technical features:

- Multilevel sorting and cooling system.

- Adjustable vibration, temperature, and feed rate parameters.

- Compatibility with various pelletizer and packaging line models.

- Wear-resistant and durable construction materials.

TechnoMashStroy equipment guarantees consistent pellet quality, optimizes production processes, and reduces finishing costs. All units undergo mandatory quality control, are certified, and are serviced by the manufacturer’s support team.