Packaging and wrapping equipment

TechnoMashStroy packaging and filling equipment offers modern solutions for precise, fast, and reliable packaging of bulk, granular, and powdered materials at agro-industrial, food, chemical, construction, and other enterprises. The filling systems are designed for dosing, filling, and hermetically sealing products in bags, pouches, or other containers.

Advantages of TechnoMashStroy packaging and filling equipment:

- High dosing accuracy — modern weighing and volumetric systems ensure minimal deviation from the set weight, which is especially important when packaging expensive raw materials or products with strict quality requirements.

- Versatility — the equipment is suitable for grain, compound feed, seeds, fertilizers, pellets, granules, and other bulk materials.

- Process automation — integration into production lines is possible, with automatic feeding, control and accounting of products, and parameter adjustment for different materials and packaging types.

- High productivity — the equipment ensures fast and stable packaging without downtime, increasing output and reducing labor costs.

- Hermetic and neat packaging — designs prevent spillage and dusting, and provide reliable sealing of containers.

- Flexible adjustment — adaptation for different container types, dosing ranges, operation speed, and other production parameters is possible.

- Ease of maintenance — convenient access to key components simplifies technical service, cleaning, and replacement of consumables.

- Operational safety — equipment is equipped with protective covers, emergency stop, and operation monitoring systems.

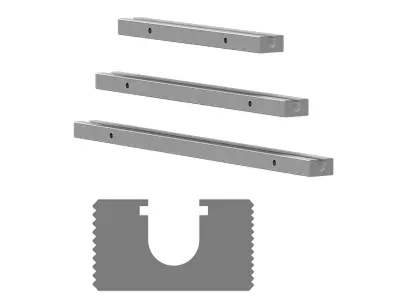

Technical features:

- Compatibility with various types of containers: bags, pouches.

- Capability to handle different fractions and material types.

- Durable design and use of wear-resistant materials for long-term operation.

- Possibility of integration with marking, conveying, and accounting systems.

TechnoMashStroy packaging and filling equipment helps optimize production processes, reduce raw material losses, and improve finished product quality. All equipment undergoes strict quality control, is certified, and is supported by the manufacturer’s service team.